At the request of the Committee on Economic Affairs of the French National Assembly for a study on Lifetime of Nuclear Plants (NPP) and New Designs of Reactors, the Parliamentary Office for Scientific and Technological Assessment has nominated Mr Christian Bataille and Mr Claude Birraux, Members of Parliament, as its Rapporteurs. Their report, adopted unanimously on May the 13th, 2003, gives answers to a variety of fundamental questions concerning electricity generation in France. How might ageing and physical deterioration affect NPP components and systems and limit their service Life ? How can lifetime management procure enhanced safety and improved operations in a cost-effective manner ? If the French Energy Policy takes a firm stand in favour of nuclear electricity generation, when will it be necessary to start to replace the oldest PWRs (Pressurized Water Reactor) ? At that time, what kind of new reactor designs will be available : evolutionary or revolutionary ? Executive Summary

The Cliff Effect At the beginning of April 2003, the nuclear power reactors in operation throughout the world amounted to 441 units, which have been operating for 20 years. With an average age equal to 18 years and 4 month, the EDF (Electricité de France) plants are the youngest among the major utilities in the world. In these circumstances, why address ageing of NPPs in France now ? Primarily because France constructed its 58 reactors over a very short period of time. Indeed, France increased its nuclear generating capacity by 50 GW between 1980 and 1990. An equally rapid decrease could remove the bulk of the French capacity if this fundamental question was not dealt with in time. This specific phenomenon can be named a "Clif Effect". If by any chance it was not possible to extend EDF NPPs life beyond their 40-year design lifetime, 13 reactors would be switched off by 2020 and an additional 24 from 2020 to 2025. The Ageing Mechanism of NPPs Resulting first from physical and chemical inputs, such as irradiation, fatigue, corrosion fretting and cracking, ageing might also come from intangible changes, such as a shortage of components, a loss of competence or an upgrading of safety requirements. In recent years, different events concerning the EDF plants have nurtured the fears that NPPs might experience premature deterioration.

In fact, 43 pressure vessel heads have already been replaced, and 11 reactors have had their steam generators changed. Nevertheless, materials have been improved with the use of the new Inconel 690 alloy which offers longer life with reduced susceptibility to corrosion. Furthermore, defects have been pinpointed on the internal coatings of seven pressure vessels. However, it has been demonstrated that these flaws are low-temperature crackings that occurred during construction and leave wide safety margins. These types of difficulty belonging to inevitable early-production imperfections, the EDF NPPs can be expected to last for at least 30 years. As far as longer-term operation is concerned, the pressure vessel and the concrete containment building represent the main limits to extending the life of a reactor, since they are still considered as non replaceable. Recent R&D findings demonstrate that the reactor pressure vessel wall embattlement as a result of neutron fluence, chemical impurities, temperature, pressure and thermal shocks, might not be as rapid and life-limiting as anticipated. Besides, efficient solutions have been implemented so as to suppress leakage through the inner containment of the double reactor containment building. Moreover the load-following operating mode of EDF reactors has long been suspected of accelerating the ageing of various components. According to the manufacturer, Framatome ANP, to the utility, EDF, and to the research body, IRSN, of the French regulatory authority, no measurement on operational reactors has ever proved that load-follow induces additional deterioration of components and systems, except for a very small number of them, such as control-rod drives. Consequently, a 40-year-or-more lifetime is predictable for most of the EDF reactors, even though it is advisable to reinforce R&D efforts on ageing and even if some EDF reactors will not have the cost-effective possibility of having their lifetimes extended beyond 40 years.

How to Enhance the Readability and Visibility of the French Safety Regulation for Investment in the Long Term Granted to the utility by a Governmental decree, the construction authorisation for a NPP does not fix any term to it, but a comprehensive safety assessment can be requested at any time by the regulatory authority, which enforces them on a ten-year basis. Every ten years, periodic safety reviews pursue a twofold objective. Firstly, the safety assessment aims at checking the maintenance of the plant-specific authorisation basis. Secondly, the safety upgrading is intended to enhance safety in the light of experience and improvements of the knowledge and to retrofit the reactor to new safety standards. As a matter of fact, the end of the first 30-year operating period is given a major importance by the French regulatory authority. The Oldest PWRs will reach this stage in 2009. The French authority will grant an additional ten-year operating authorisation on a case-by-case basis. Compared to the NRC, which gives operating licenses for a fixed term of 40 years and license renewals for an additional 20-year period, the French system is more stringent. Concerning NPP lifetimes, at the end of each ten-year safety review, the French regulatory authority informs the utility that it is not opposed to restarting the reactor for an additional ten-year period. Instead of this restrictive wording, an articulate authorisation statement would bring better value to the utility. One should also wonder if the French regulation might be reshaped so as to incorporate long-term authorisations, which would give the visibility requested by every energy strategy or policy.

The Economic Dimension of Extending Lifetimes NPP lifetime extension has a vital impact on the utility’s bottom line. For an amortised nuclear reactor, the cost of generating electricity amounts to 12 € / MWh, compared with the 28-30 € / MWh cost of generating electricity from a newlybuilt nuclear reactor or a gas combined cycle. As a consequence, a one-year extension of an amortised reactor saves the utility one hundred million € in terms of fuel, operation and maintenance costs. Bringing good money to the utility, lifetime extension deserves a high priority but can not be its only strategic goal. The same priority should be given to making new reactors available for replacement. If not, the utility might be compelled to extend lifetimes beyond what is reasonable. Without a Replacement Solution, the Necessity of Extending Lifetime beyond Reasonable Limits The evolution of EDF’s plants in the coming years has recently been simulated by the utility itself, which highlights the interaction between the replacement schedule and constraints on lifetime extension. In the following scenario, the aim is to rebuild by 2050 a nuclear generating capacity of 50 GW, which corresponds to two-thirds of base-load capacity. During the 2020-2035 period, those reactors which are constructed up to 25 GW belong to Generation III or III+. Afterwards, from 2035 to 2050, Generation IV reactors, which are supposed to be then available, are chosen and constructed. To face such a situation, there is no other choice than to extend the average lifetime of all the plants to 48 years, a limit that can not been guaranteed in any way. If the replacement process were to begin in 2025, the average lifetime should then reach 52 years. Finally, if it was decided to skip Generation III or III+ reactors and consequently to postpone replacement until commercial Generation IV reactors are operational, it would be necessary to operate current reactors until their 59th year on average. EDF’s conclusion, which is endorsed by the French Ministry of Energy, is therefore clear. Unless considerable risks are taken on the average lifetime of EDF’s 58 reactors, it is absolutely indispensable to put on the grid a set of new reactors by 2020.

Reactors for near-term deployment are all evolutionary reactors, designed on the same technological basis as the existing nuclear power plants, so as to benefit from the experience gained from the latter’s construction and operation. Coming on line to start commercial operation around 2015, these reactors are also designated as "Generation III or III+" reactors. In contrast, revolutionary or Generation IV reactors incorporating technological discontinuity with inservice NPPs aim to be operational in 2035. The main competitors for near-term deployment of PWRs are the EPR (European Pressurised water Reactor) developed by Framatome ANP, the AP 1000 reactor (Advanced Passive reinforced pressurised water reactor) developed by Westinghouse-BNFL and the VVER AES 91 & 92 reactors from the Russian Minatom. Belonging to the category of boiling water reactors, the ABWR (Advanced Boiling Water Reactor) from General Electric is another tough competitor, together with the SWR 1000, from Framatome ANP, a boiling water reactor with passive safety features.

The EPR, a Near-Term Deployment PWR with Enhanced Safety and Competitiveness Resulting from a Franco-German co-operative approach uniting safety authorities (up to 1998), vendors and utilities, the EPR basic design is aimed at offering improvements in safety and economics, compared with operating nuclear reactors. Accident prevention is reinforced by physically separated; diverse and redundant back-up systems. Various safety features contribute to reducing the probability of a severe accident such as core melt, with special devices mitigating consequences, like a core catcher avoiding concrete interaction and recombiners preventing hydrogen combustion.

Operating costs will be reduced by a high average fuel burn-up which should reach 60 GWd/t instead of 47 GWd/t in 1997 for EDF reactors, the cycle length being increased to 18 months as opposed to 11 months for N4 type reactors, with uranium consumption reduced by 17 %. Outages should last only 16 days versus 47 days for N4 reactors, the 10-year periodic safety review being halved. The EPR average availability should reach 91 % against an 81 % average availability for the total number of EDF NPPs in 2001. Operating improvements should lower the EPR cost of generating electricity by 10 % compared with the N4’s. The EPR’s production cost, which is estimated to be 27,7 € / MWh, is more competitive than that of the most recent gas combined cycle plants. With a series of 10 units sharing the first-of-a kind costs, the investment cost totals 2.6 billions € per unit, which is equivalent to 1,628 € / kW. Even if the series was limited to 4 units, the generating costs would reach 33 € /.MWh, matching those of a gas combined cycle, while being far less sensitive to fuel cost increases. Tough International Competition As previously stated, EPR is not the only reactor on the market. An advanced 1350 Mwe boiling water reactor (BWR), the ABWR from General Electric, shows simplified reactor system and containment design, which are important advantages over standard BWRs. Another asset in the international competition, two ABWRs are currently being operated in Japan, and two more are being built in Taiwan, a situation that none of the competitors can match. Although its portfolio comprises the SWR 1000, Framatome ANP has no record of operation with this reactor for the moment. Among EPR’s competitors, the Russian VVER AES 91/92 and Westinghouse’s APWR 1500 are to be mentioned, and especially Westinghouse’s AP 1000. The AP 1000 is a 1000 MWe pressurised water reactor which features passive safety systems using natural forces such as gravity, natural circulation and compressed gas. Relying on fewer valves, pumps, pipes and cables, its advanced passive design is intended to reduce capital costs, maintenance and operations testing while providing safety improvements. A high level of modularization is incorporated in order to shorten construction schedules to 36 months, an additional 6 months being however necessary before putting it on the grid. Currently under review by the US Nuclear Regulatory Commission, the AP 1000 appears as an interesting combination of Generation II PWRs’ experience feedback with innovative design based on proven technology component. Thus, in the midst of the tough international competition which already exist among on vendors bidding for Finland’s 5th nuclear reactor, the EPR seems to be in good position.

The Construction of the EPR in France, a Guarantee against Various Risks and the Appropriate Instrument to Smooth out the Replacement of EDF’s Reactors In order to cope with the Cliff Effect which might wipe out in a very short period of time the bulk of French electricity generating capacity, is it mandatory to launch the first EPR construction. A number of reasons plead for the Government to give the go-ahead to EDF. Not only the vendor, Framatome ANP, but also EDF and the French Regulatory Authority, not to mention their German counterpart, have already invested a considerable amount of time and R&D money so as to finalize EPR’s basic design, technical guidelines and detailed conceptual design. In the field of safety, the French nuclear safety authority has clearly stated that the EPR’s safety options might have to be revised, should its construction be delayed any further. In addition, an alternative fossil-fuelled power plant, such as a gas combined cycle, which is frequently cited as the most environmentally friendly electricity generation technology, is a major contributor to air pollution and climate change, since the yearly air emissions of 520 Mwe gas combined cycle amounts to 2 millions tons of CO2 and over 600 tons of chemical pollutants. An electricity generating strategy relying on natural gas would entail a double risk. First, a rise in the natural gas price would sharply increase the cost of generating electricity, since the fuel costs account for 80 % of the total cost, against about 15 % for an advanced nuclear power plant. In addition, France would not be in accordance with two of its international commitments, the Kyoto Protocol for greenhouse gas emissions and the European Directives related to airborne NOx and SOx emissions. Another key reason is the absolute need to spread and smooth out the replacement of current nuclear reactors, for industrial and economic reasons. In the coming years, it is compulsory not to repeat the 10-15 year sprint performed by the French nuclear sector during the 1980’s. Too fast a pace of construction requires massive investments. If too rapid, an installation programme inevitably increases the risks of material or component flaws. In addition an overly concentrated effort paves the way to long periods of depressed activity, which is contrary to the efficient use of competences and equipment in the long term. After having taken into account administrative procedure and construction time, EDF has assumed its responsibilities as a utility, in disclosing, on April the 3rd of 2003, its intention to build an EPR as soon as possible, so as to guarantee the replacement of its nuclear plants on the human, technical and economic levels. There is no reason why EDF should be forbidden to do so.

To develop new reactors for the long term, a number of technological breakthroughs will have to be made, which implies a revival of nuclear R&D. A Number of Technological Breakthroughs When considering the very long term of nuclear energy, quantum leaps have to be made in four main directions in order to overcome the difficulties nuclear energy has had to cope with from the beginning. The first technological breakthrough to work out concerns safety : the ultimate nuclear reactor should be intrinsically safe, with a probability of a core melt equal to zero even in case of a loss-of-coolant accident. The second technological advance : these reactors should generate fewer nuclear wastes than light water reactors and should serve for recycling and transmuting Generation II, III and III+ wastes. The third technological breakthrough : some of these reactors should be modular, with a power-per-unit lower than those of current commercial reactors, so that they might fit various types of electrical grids in developed or developing countries. The fourth technological breakthrough : these reactors should be versatile and serve various types of applications, i.e. electricity generation, combined electricity/heat production, hydrogen production or desalination of seawater. The first designs of new reactors to appear in recent years have been the sub-critical nuclear reactor popularised in 1993 by Professor Rubbia, then the PBMR (Pebble Bed Modular Helium Cooled Reactor) which both belong to the group of high temperature reactors. A second project set corresponds to the Generation IV Nuclear Energy Systems Initiative, launched in 2001 by the US Department of Energy, which has introduced international co-operation in selecting new systems. This co-operation is hosted by the Generation IV International Forum (GIF), an informal group gathering nuclear research centres from ten nuclear states (USA, France, Japan, UK, Canada, South Korea Switzerland, South Africa, Argentina and Brazil). Simultaneously, in the perspective of nuclear waste recycling and transmutation, a conceptual rethinking of sub-critical reactors has paved the way to Accelerator Driven Systems (ADS) which gained great interest as soon as the nuclear fuel cycle moved to the top of the agenda. All these projects are re-starts of former concepts which had already been studied, designed and even tested during the 1960’s and the 1970’s : they were abandoned at that time due to technological impasses and their lack of competitiveness against light water reactors. The challenge is to reverse the situation thanks to technological improvements. The High Temperature Modular Reactors High temperature modular gas reactors represent one among several avenues of research. The PBMR is a 100 MWe helium cooled projected reactor, using pebbles made of coated fuel particles and developed by Eskom, the South African utility, with the temporary help of Exelon, an American utility, and currently with that of BNFL. Raising wide initial interest because of its projected response to the needs of developing countries, the PBMR seems to be handicapped by its poor economics.

The GT-MHR results from an American-Russian co-operation in high temperature reactors tested during the sixties and the seventies. At the very beginning, the project was aimed at helping to maintain nuclear competences in Russia after the collapse of the USSR. Nevertheless, following the signature of the START II treaty the GT-MHR was refocused in 1994 as a burner of plutonium coming from dismantled nuclear weapons. On the technical side, GT-MHR has been designed as a 300 MW reactor, a good compromise, according to its designers, between a low capacity indispensable to reach intrinsic safety and a high capacity indispensable to economies of scale and competitiveness. One GT-MHR module schould burn 250 kg of plutonium per year. A first module is scheduled to be built in Russia at Seversk and to become operational in 2010 according to some experts, or later on in 2015-2016 according to other experts’forecasts. Generation IV Systems Among the six fuel-reactor systems selected by the Generation IV International Forum (GIF), the VTHR (Very High Temperature Reactor), which should be a 600 MW reactor, has probably the most promising future. Belonging to the same category as the GT-MHR, the VHTR should differ over a higher temperature – 1000-1100 °C against 800-850 °C, which represents a huge advantage and would open a wide range of additional markets. Initially, the VHTR fuel was to be a mix of highly-enriched uranium and thorium. Now the purpose is to make it suitable for burning low-enriched uranium, plutonium, or a mix of plutonium and minor actinides. In that case which is controversial, the VHTR would recycle nuclear wastes generated by PWRs or BWRs. Moreover, owing to the high temperature of the helium flowing from the core vessel, the VHTR should be perfectly adapted to deliver high-temperature heat for thermo-chemical processes, among which hydrogen production stands first. In the case where all these objectives are met, the VHTR should be the prominent nuclear reactor for the second half of the century. A first demonstration reactor is expected around 2020. Fast neutron reactors are also considered promising for the long term. In spite of the closing of Superphenix in France, sodium cooled fast reactors have still a future, according to nuclear researchers not only in France but also in the United States, Russia and Japan. Lead or lead-bismuth cooled fast reactors are also being considered for low-capacity units which might be adequate for desalination or electricity-generating needs in isolated areas. Gas cooled fast reactors seem also a top priority, although many difficulties will have to be overcome. Reactors for Waste Transmutation Among the various markets for nuclear reactors for long-term deployment, waste transmutation is of the utmost importance. Of course, when selecting new reactors for 2030, one of the main parameters to take into consideration will certainly be their volume of nuclear wastes and radiotoxicity per MWh sent to the grid. But such a condition will not remove the problem of the light water reactor wastes. Consequently, the nuclear sector will have to count on specific reactors dedicated to waste transmutation.

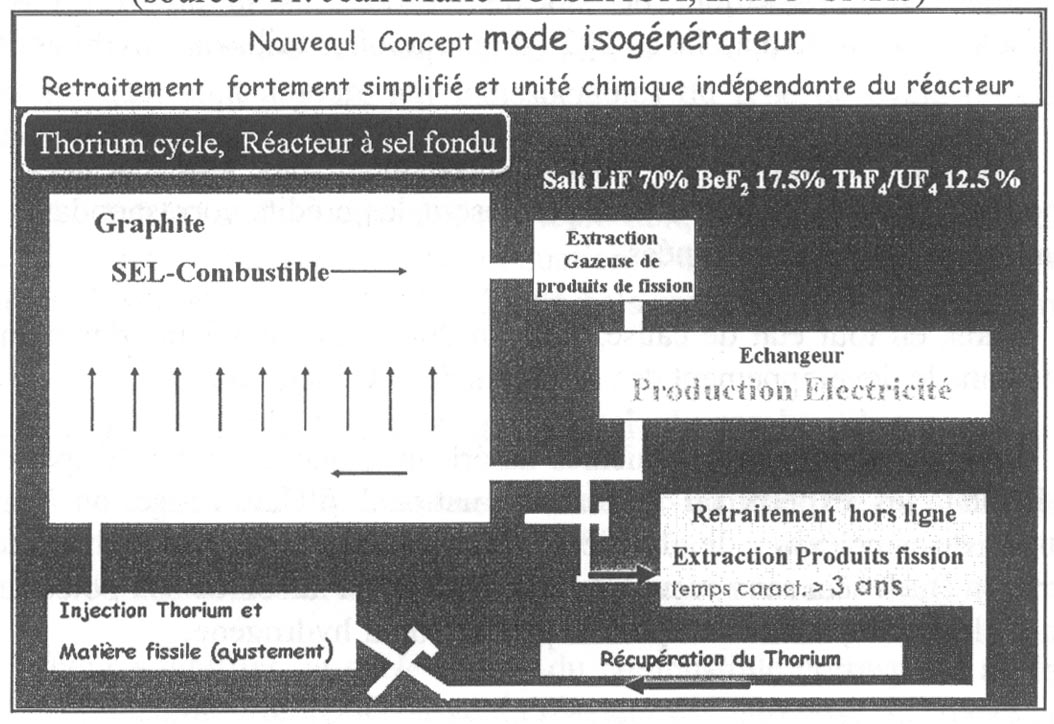

For that purpose, some experts recommend developing at first fast neutron reactors because they should be the best transuranic burners. In contrast, other experts plead for Accelerator Driven Systems, which are however seen as an imperfect instrument insofar as they cannot use plutonium as a fuel, unlike fast reactors. Certainly, considering its importance, the debate on this point should be widened rapidly. Molten Salt Reactors As far as long-term energy supply is concerned, other innovative fuel-reactor systems must be investigated. Thorium 232-Uranium 233 fuels and molten salt reactors might offer interesting solutions. Thorium is three or four times more abundant on earth than uranium, and is spread over all the continents. Besides, molten salt reactors using thorium-uranium fuel burn less fissile material than fast reactors for the same amount of electricity generated. Last, their wastes contain only 20 kg of americium and curium, against 750 kg for a fast reactor delivering the same quantity of electricity (9 TWh). Although the systems thorium 232-uranium 233/Molten salt reactors are very promising in the long term, the Generation IV International did not grant them a top priority, which should lead the French research institutions to stress this avenue of research. International Cooperation and Pluralism in R & D Because of the high level of competences required by the related industry, nuclear energy does not seem to have a wide market share in the near future, even though climate change should emphasize its advantage as a CO2-free source of energy. Nevertheless, the huge R&D investments to be made for developing new types of reactors will not be affordable for any one country, unless they are shared on the international level, within a framework of shared costs and shared profits as is the Airbus scheme, a reference in this type of cooperation. All French R&D institutions have to be mobilized and energized in order to play a leading role in the international competition and to install a real pluralism in the French nuclear landscape, a condition for transparency and efficiency. May 2003

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||